-

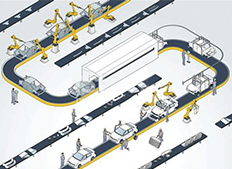

- Designing automotive assembly line

-

- Manufacturing assembly units

-

- Installing and commissioning the assembly line

-

- Modernize the equipment and increase capacity

The parts of the automotive manufacturing lines that JDSK designs and constructs

-

- Welding Lines for Automotive ComponentJDSK can provide different types of automotive welding systems according to the vehicle type, drawing, digital model.

-

- Automotive Paint ShopVehicles body must be cleaned and conditioned to ensure the best possible paint job. Auto paint shop is not just about color. The paint also protects the body.

-

- Automotive Assembly LineJDSK can provide automotive assembly and fabrication lines for any type of vehicle. We can equip the automotive assembly system according to your demands.

-

- Automotive Testing and Inspection LineThe automotive testing and inspection line is mainly used for automobile performance testing.

In the above system, JDSK offers outstanding advantages especially with our automotive welding line, automotive holistic production painting line and automotive assembly and fabrication line. JDSK can also upgrade some of the processes according to the situation of the customer's current manufacturing line to improve the efficiency and production quality.

JDSK can transform the existing manufacturing lines by changing or adding various key pieces of equipment or assembly units based on the customer's production plan to meet the needs of production. JDSK designed and simulated the production processes without interrupting the customer's normal production operations.

JDSK has more than 10 years of extensive experience in providing comprehensive solutions regarding the design and planning of automotive manufacturing lines for producers of sedans, pickup trucks, SUVs, heavy duty trucks and buses. Our technical experts have been producing, installing, maintaining, and upgrading automotive manufacturing lines for years and understand the ins and outs of the equipment. Compared to our competitors, JDSK has outstanding advantages when it comes to welding, painting, assembly, and testing capabilities.

We mainly provide services to small and medium-sized automotive manufacturers with our semi-automatic or fully automatic manufacturing lines with a minimum investment of 2 to 3 million dollars each. We also provide supporting equipment and system services for large-scale automotive producers like Audi and Volkswagen. In addition to automotive production solutions, we also provide solutions for construction machinery, agricultural machinery, and three-wheeler production.

JDSK has provided automotive manufacturing line design and integral automated assembly system manufacturing service to many automotive manufacturing companies. Currently, some of our main customers including FAC Lingyuan Automobile, Jiayuguan Yite Automobile, Hubei Gucheng Yifei Automobile, Lanzhou Asia-Pacific New Energy Automobile, Wuzhoulong New Energy Motors, Guangxi Hua’ao Automobile, Shaanxi Tongjia Automobile, Algeria PPA Auto and etc. JDSK has built SUV car manufacturing lines, light duty and heavy duty truck manufacturing lines, bus manufacturing assembly lines, electric bus assembly lines, construction machinery manufacturing lines, three-wheeler production lines and so on. And these successful manufacturing lines are still operating normally and efficiently to this day. In addition, JDSK has provided equipment replacement and upgrade services to many automotive manufacturing companies. At the same time, JDSK will provide all kinds of needed equipment and parts of the manufacturing lines to the customers. Many automotive manufacturing companies have praised JDSK as a quality accessories supplier.